Career Planning Program for Self-employment

The HUB strongly encourages and supports community employment, but for many individuals with autism, cognitive delays, communication impairments, or extreme sensitivity to common, unavoidable stimuli, the sights, sounds, crowds, and distractions in typical workplaces are distressing and overwhelming.

Self-employment allows you to work at your own pace, or projects and activities that you enjoy, performed in an environment of your choosing, without distractions. Because of all these advantages, we have designed our very own program to prepare for self-employment using 3D Printing. Our 3D Printing Self-Employment Program (3DSE) provides countless opportunities and growth for everyone!

What is “additive manufacturing” and “3D printing” and why is the process well suited for you?

The term 3D printing can be used to define several different types of additive manufacturing processes. The HUB’s Career Planning program focuses on the most common form, Fused Deposition Modeling (FDM), where a machine deposits raw materials in a layer-by-layer format utilizing a computer numeric control (CNC) program to produce a solid object. The machine continues to add material until the object is complete, hence the term “additive manufacturing.”

This is starting to sound technical, isn’t it? 3D printing can be very technical, but then again, so can your smartphone, and just like your smartphone, you don’t have to know all the technical aspects of a 3D printer to be successful at using it! In fact, most of us do not understand the electronics or programming that makes a given device (such as a phone, TV, and car) work, but we use them every day.

If you are someone who likes working on modern technology and creating, but find it hard to maintain community employment, this program is perfect for you!

Barriers to Community Employment

Self-employment can be very helpful for a wide variety of individuals, including people with physical, cognitive, or neurological impairments. Some of the most common barriers to community employment are behaviors often associated with Autism Spectrum Disorder (ASD), one of the most common diagnoses we see today. These can include communication, sensory sensitivity, self-stimulation, and other behaviors. We will break down the top four ordinary obstacles and explain why 3D printing as a means of self-employment is exempt from all of them. If you experience any of these or want to further explore, click the plus to read more!

Self-Employment for Individuals with Special Needs Today

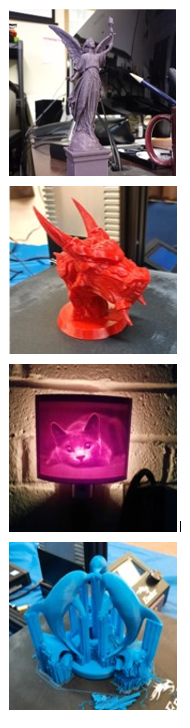

When it comes to self-employment for individuals with special needs, especially when the diagnosis involves a cognitive delay or neurological challenge, making small crafts and woodworking items to sell online or in a consignment shop is probably the most common. Although there is great pride in making something and joy to be felt when it is purchased, let’s face it, most items are mostly decorative. Crafts are also time consuming, messy and it is difficult to reproduce the same item over and over. 3D printing has many advantages over handmade items.

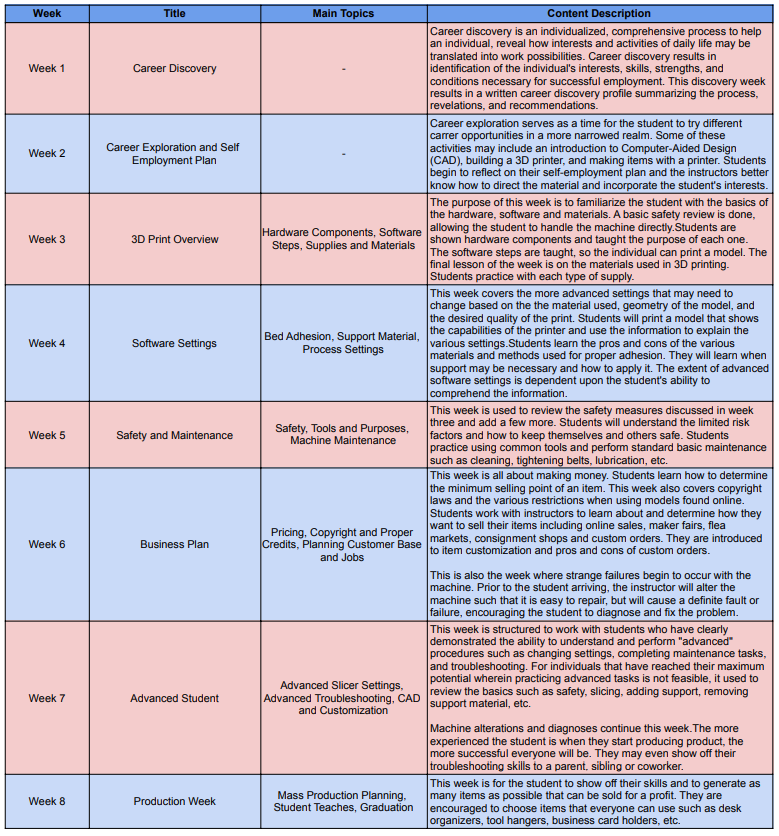

Program Breakdown

We have told you about the advantages of the 3DSE program, but what does it look like? Learn about our 8-week curriculum and some of your peers that have gone through the program by clicking on the plus signs below!