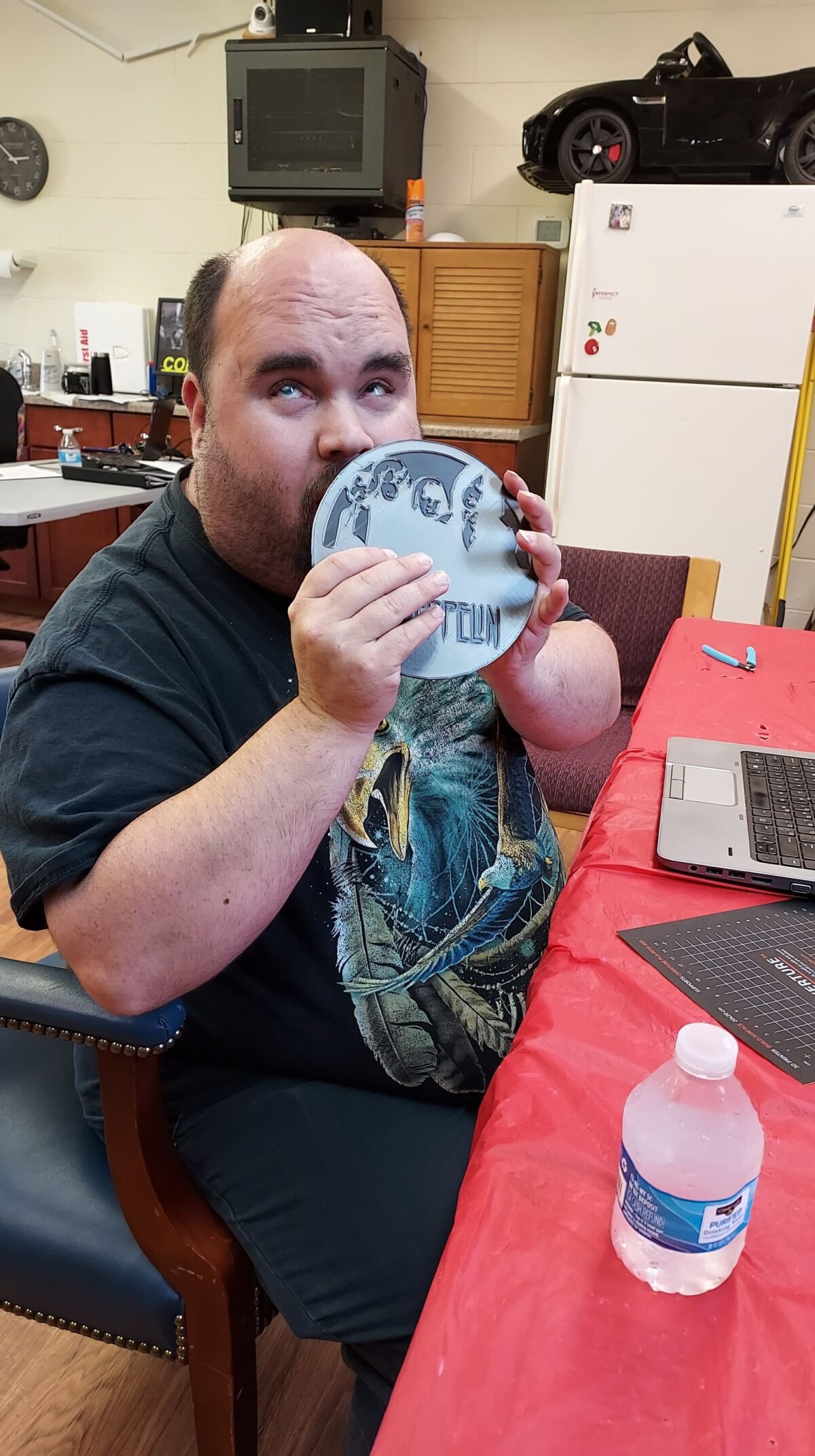

We’d like you to meet Kenny Peyatt Jr. the founder of “Blind Faith in 3D”, a 3d printing company! Thanks to a collaboration of The HUB, the Clark County Board of DD, The Springfield Foundation, and an “innovative use of technology” grant from the state of Ohio he now has a custom 3D printing set up modified specifically for his sight impairment!

In 2021 The Hub was awarded an innovative use of technology grant, that would enable us to purchase equipment and structure a formal training program to teach 3d printing to individuals who struggle to work in the community. In 2022 we were contacted by the Clark County Board of DD about an individual who was very interested in the program. Although we have previously taught this skill to several individuals with varying abilities, Kenny introduced a unique challenge in that he has been blind since birth. At first we were concerned due to the amount of software skills and hands on tasks required when 3d printing. That was until we learned that Kenny had a degree in information technology. Although we knew this would introduce some unique challenges, after meeting with Kenny, we knew instantly that we could make this work! Clark County Board of DD funded an 8 week training course that ultimately required the use of four different software programs and multiple adaptations to the equipment. These included the slicer (the software used to create a printing file), Pronterface (the software that enables Kenny’s pc to communicate with the printer), NVDA ( Non visual digital assistant- a screen reader designed for sight impairments) and JAWS ( another accessibility program that replaces the use of a mouse for a sight impaired person- hence the ” jaws theme” music heard in the video😉.) Kenny completed the course with flying colors! His prior knowledge of computers and new found 3d printing skills were so impressive that it inspired his representative from The Clark County Board of DD to seek a grant to purchase the equipment that Kenny would need to create his own 3D printing company. As a result we were given the opportunity to demonstrate Kennys amazing abilities to The Springfield Foundation, located in Springfield Ohio, which gave the foundation no doubt that this would a worthy investment!

With the funds secured, the fun begins! Now we didn’t just purchase any printer, we were able to purchase a Prusa I3 MK3s, a high end unit known for its reliability, technical support, and precision! The unit was upgraded with a Prusa MMU (multi material unit) designed to manage 5 filaments! This gives Kenny the ability to print in multiple colors and multiple materials without the need for manual filament changes. Our goal was to make the manual process as simple as possible for Kenny so he can be self-sufficient.

Even though the high end equipment helped to solve some of the challenges, anybody with printing experience knows that managing 5 filaments is no easy task. Time for the founder of The HUB (aka, Dad) to do his thing! Cue the rolling cart, a madman’s project. Dad knew that the system would need to be portable, so that it could be easily transported for shows and demonstrations. Aware that filaments could fall or get tangled, precautions had to be taken! Steps for installing new filament (which is not an easy task for anyone) would also have to be simplified, tools would need to be easily accessible, and the area in which the filament is stored needed to be in a controlled environment. Every manual task required for this complex system would have to be completed without the use of sight. After 100 hours of design work , a few thousand nuts and bolts and several rolls of filament later Kenny’s cart was complete with multiple adaptations that enabled Kenny to work completely independently. The 5 port, air tight, dehumidified enclosed filament management area (Whew!) ensures that his materials are well maintained and easily accessible. Braille labels in each bay help Kenny keep track of which filament is where. Custom filament access points with magnetic latches give Kenny the ability to fine tune his filament without the use of any tools. A strategically placed phone holder allows Kenny to take videos of his prints and remote support when visual inspection is necessary. An integrated surge protector provides outlets for a phone charger, laptop, or other electronic devices! A single switch powers the printer and environmental controls. To finish it off we added custom multi colored name tags printed using the Prusa MMU unit! By far this has been the coolest 3D printing project I’ve seen dad create! Stay tuned for more information on Kenny and his company. If there is a person in your life that is limited by the need for an adaptation, please reach out!